Precision Boring Mills for Exceptional Performance

Discover Our Range of High-Quality Boring Mills for Accurate and Efficient Machining.

-

New machines

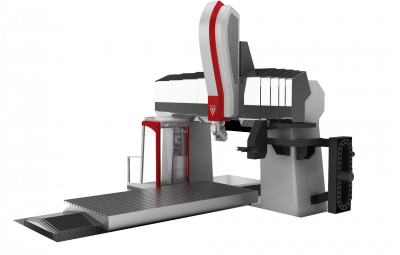

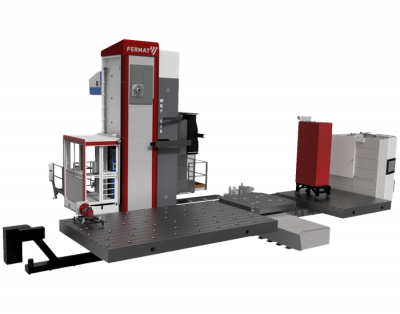

Fermat New Horizontal Boring and Milling Machines

Click here to find out more

-

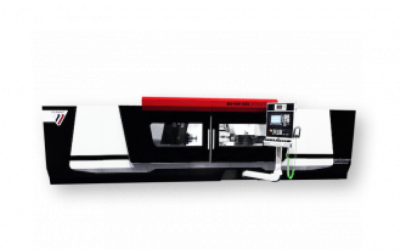

Stock machines

Machines in stock or with short delivery time

Click here to find out more

-

Used machines

Browse our large selection of used metalworking machines

Click here to find out more

-

Spare parts

Parts for Fermat, TOS Varnsdorf, SKODA, TOS Lathes & other brands

Click here to find out more

SERVICE AND SPARE PARTS

Service and Quality Spare Parts for Your Needs

ABOUT US

TOS America Inc.

The FERMAT brand of boring mills is one of the most in-demand in Canada, due to the high quality of the equipment supplied by the company.

TOS America Inc. carries over five decades of experience with us into every transaction, so you can be confident in our knowledge and expertise when recommending potential FERMAT boring mills. We aim to provide top class customer service to compliment our state-of-the-art equipment. Our knowledgeable staff is ready to answer any questions or concerns you have about our FERMAT boring mills. Our boring mills are among the best in terms of quality and longevity.

Blog

Latest news

03/31/2022

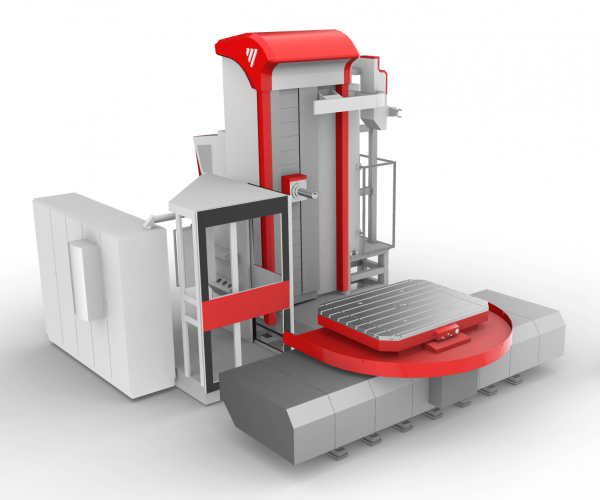

MG - the leading manufacturer of plate roll and section bending machines in Europe. And now also a proud owner of FERMAT horizontal boring mill, WFT 11.

11/01/2021

But for the first time the meeting did not take place in Brno, but in Nuremberg, at one of our dealers - at company Och.

03/18/2021

WFT 13 is our best-selling machine and this is one of many virtual tours of the machine that we have prepared for you.